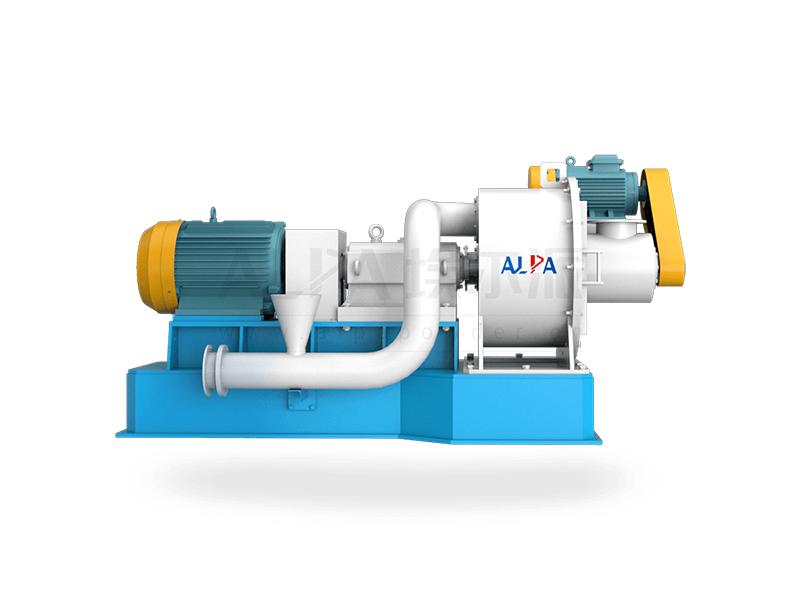

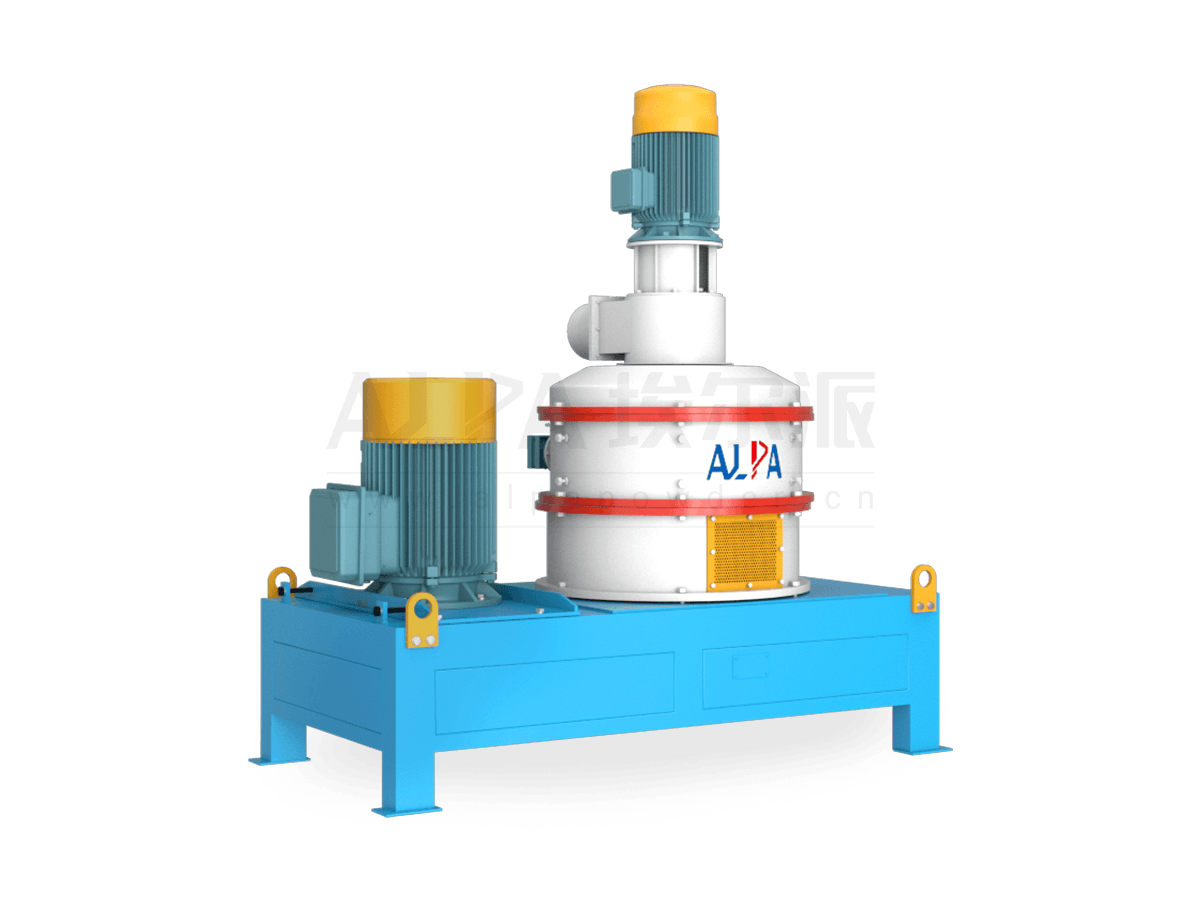

CSM-V Air Classifying Mill

Material is evenly fed into grinding chamber by quantitative feeding devices, strongly impacted by high-speed rotating grinding disc. At the same time, it is subjected to centrifugal force and collides with grinding ring gear and is subjected to various comprehensive forces such as shearing, friction and collision to finish grinding. The milled material moves to classifying zone in the mill host with airflow. Rotating speed of classifier is control by inverter, separates the coarse and fine materials, the product that meet fineness requirement will be output and enters cyclone collector and bag filter with airflow, coarse powders return to milling zone for secondary grinding.

Product Size:D50:1~45μm

Application area:It is widely used in non-metallic minerals (below Mohs hardness 5), chemical industry, inorganic salts, medicine, food, pigments, dyes, pesticides, battery materials, minerals, refractories, new materials and other industries.

采用德国技术,高精度机械粉碎机,并不断技术创新升级,适用50目-2500目(300um-5um)。经典结构,引进德国技术,应用广泛,源自传统的空气分级磨(ACM),超过1000台套的应用。广泛应用于非金属矿物(莫氏硬度5以下)、化工、无机盐、医药、食品、颜料、染料、农药、电池材料、矿物、耐火材料等行业

-

Performance characteristics

- Available D50: 2~45μm.

- Classifying wheel is vertical installation.

- Integration of grinding and classifying, rotating speed of classifying wheel is adjustable to obtain ideal particle sizes.

- Compact structure and small floor space, easy to disassemble and clean, seamless and smooth design.

- Lower energy consumption, wide application, high cost-performance.

- Key parts like hammer, gear ring and classifying wheel are made of wear-resistant material, and also ceramic ensuring non-contact with metal throughout the grinding for high purity of the final product.

- Grinding is in closed system, low dust and noise, clean and environmentally friendly.

- PLC control system, easy operation.

- Low noise design.

- The motor can be connected with belt to increase rotating speed.

- Can be used in series with multi-stage classifiers to produce multiple sizes.

- Optional explosion-proof design, meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials.

- High-temperature, low-temperature, normal-temperature, airtight cycle, Inert gas cycle designs are available, for different grinding requirements of different materials.

Working principle

Technical parameter

| Parameter | CSM-280V | CSM-350V | CSM-510V | CSM-710V | CSM-1100V | CSM-1250V | |

| Power (kW) | Grinding Disc | 7.5 | 11~15 | 22~30 | 45~55 | 90~110 | 132~160 |

| Classifier Impeller | 1.5 | 2.2 | 4~5.5 | 7.5~11 | 15 | 18.5~22 | |

| Feeder | 0.55~1.1 | ||||||

| Rotate Speed(r/min) | Grinding Disc | 7500 | 6200 | 4200 | 2800 | 2100 | 1700 |

| Classifier Impeller | 500~4500 | 500~4000 | 400~3000 | 300~2500 | 250~2000 | 200~1600 | |

| Feeder | 20~100 | ||||||

| Max Air Flow (m3/h) | 700 | 900 | 3000 | 5400 | 10000 | 15000 | |

| Product Size(μm) | 5~300 | 10~300 | |||||

| Production Capacity(kg/h) | 2~100 | 10~400 | 15~600 | 30~1200 | 60~1500 | 300~3000 | |