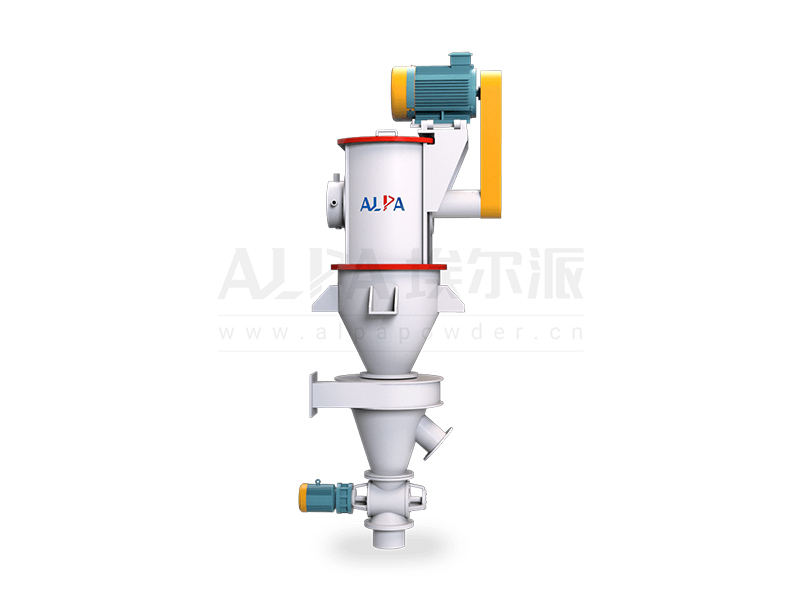

FW/HTS Single Classify Wheel Air Classifier

Under the suction force of the fan, the materials move to the classification area at a high speed from the material inlet at the lower end of the classifier with the updraft. Under the strong centrifugal force generated by the high-speed rotating classification turbine, the materials are separated, and the fine particles meeting the particle size requirements enter the cyclone separator or dust collector through the blade clearance of the classification wheel. The velocity of some fine particles entrained by coarse particles disappears after hitting the wall, and drops to the secondary air outlet along the cylinder wall. After the strong scouring effect of the secondary air, the coarse and fine particles are separated, the fine particles rise to the secondary classification in the classification area, and the coarse particles drop to the discharge port.

Product Size:D50:1~45μm

Application area:It is widely used in chemical industry, minerals (especially suitable for the classification of non mineral products such as calcium carbonate, kaolin, quartz, talc and mica), metallurgy, abrasives, ceramics, refractories, medicine, pesticides, food, heal

Under the suction force of the fan, the materials move to the classification area at a high speed from the material inlet at the lower end of the classifier with the updraft. Under the strong centrifugal force generated by the high-speed rotating classification turbine, the materials are separated, and the fine particles meeting the particle size requirements enter the cyclone separator or dust collector through the blade clearance of the classification wheel. The velocity of some fine particles entrained by coarse particles disappears after hitting the wall, and drops to the secondary air outlet along the cylinder wall. After the strong scouring effect of the secondary air, the coarse and fine particles are separated, the fine particles rise to the secondary classification in the classification area, and the coarse particles drop to the discharge port.

-

Performance characteristics

- Available D50:2-45μm.

- Suitable for precise classifying of dry micron material.

- Classifying efficiency (extraction ratio) can be 60%~90%.

- The linear velocity of vertically installed classifying wheels is up to 70m/s.

- Speed of wheel is controlled by inverter, particle size can be adjusted freely.

- System equipped with muffler operating under negative pressure, meet environmental requirements,noise <76dB(A).

- The inner lining is made of alumina, no metal pollution, meeting the requirements of high purity materials.

- Grinding is in closed system, little dust, low noise in a clean and environmentally friendly process.

- PLC control system, easy operation.

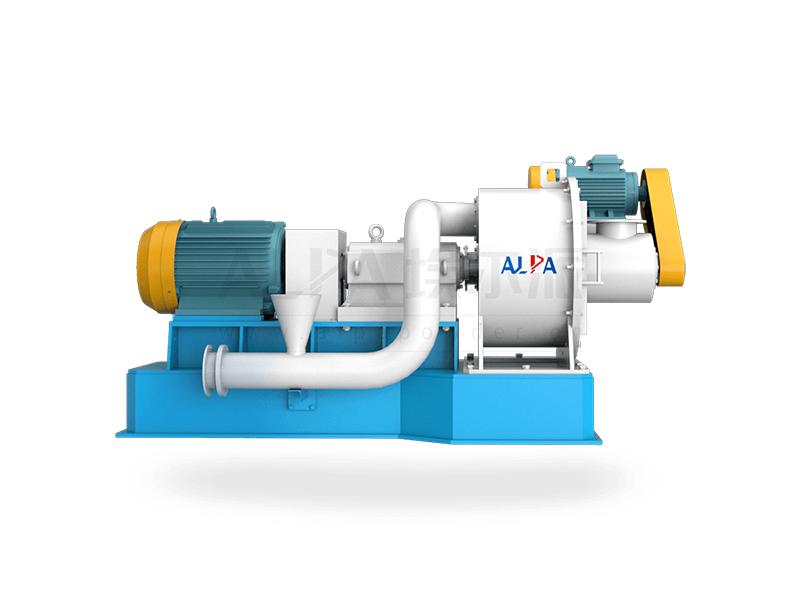

- In conjunction with ball mill, table roller mill and Raymond mill to form closed circulation.

- The motor can be connected with a belt, which is stable and reliable, realizes high speed and increases the speed, and breaks through the problem that the well-known motor brand does not have a high-speed motor.

- Optional explosion-proof design, can also be upgraded to a nitrogen circulation system to meet the processing needs of flammable and explosive oxide materials.

Working principle

Technical parameter

| Parameters/specifications | FL300 | FL360 | FL450 | ITC-4 | ITC-5 | ITC-6 |

| Production Capacity(kg/h) | 20~1000 | 300~2000 | 1000~3000 | 8000~15000 | 15000~20000 | 20000~30000 |

| Product Size(d97:μm) | 6~150 | 5~150 | 5~150 | 10~150 | 15~150 | 20~150 |

| Classifying efficiency(%) | 60~90 | 60~90 | 60~90 | 60~90 | 60~90 | 60~90 |

| Installed Power(kW) | 11.5~42.5 | 18~60 | 63.5~105 | 120~160 | 90~200 | 170~310 |